The Results Are in...Our Clothes Don't Fit

Those of you who know me know that I've been talking about garment fit for over twenty years. Back in the 1990's, when international trade and overseas apparel production was in its ascendance as manufacturers sought to capitalize on low labor costs overseas, fit really started to become an issue for consumers. Separated by an ocean and a continent or two, designers, patternmakers, and samplehands were no longer working side-by-side creating garments that would perfectly conform to, and therefore beautifully fit, the human body.

My technical reference book: The Apparel Design and Production Handbook was an attempt to standardize garment fit in the fashion industry. And it did just that...for a short while. When the first edition of the handbook was published in 1999, the goals for most brands and retailers included quality and good fit, even though their production was going offshore. At that time, fashion companies developed on average 4.75 fit samples per style, and 33% of garment returns were taken back to the stores due to poor fit; however, that was then and this is now.

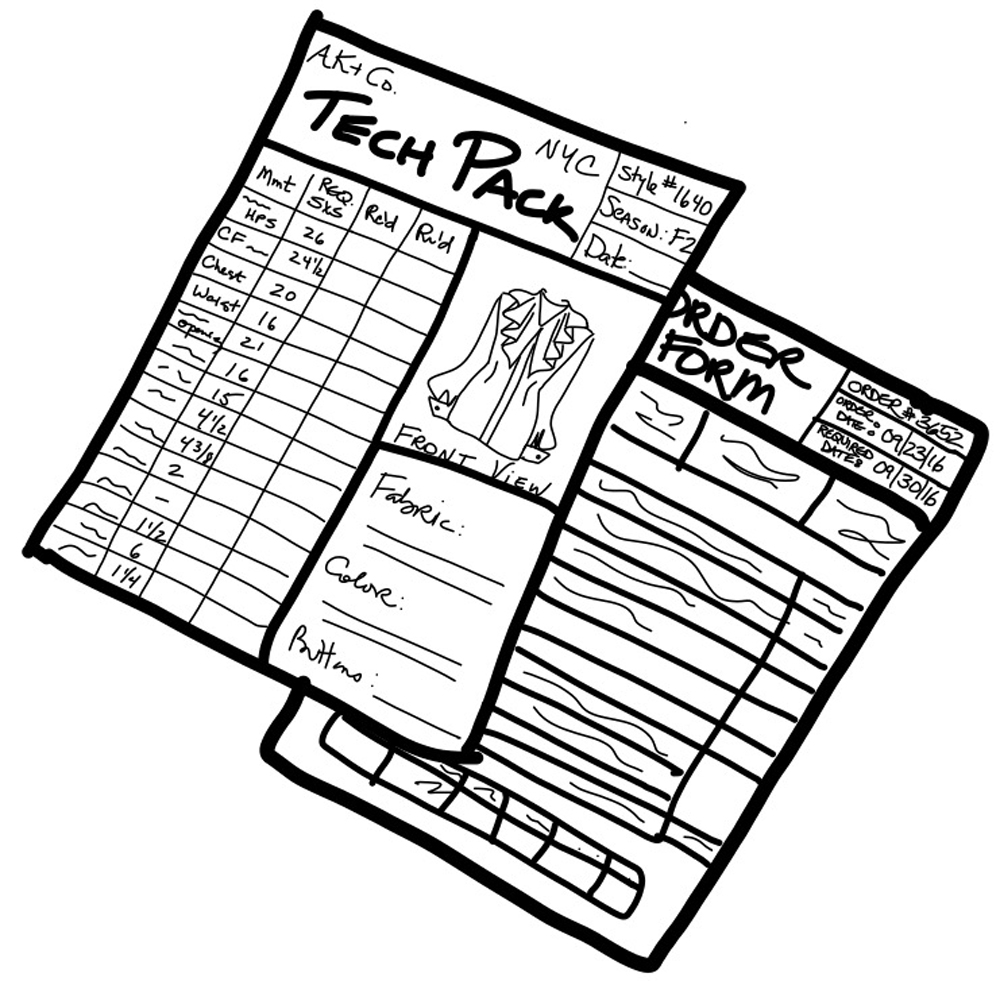

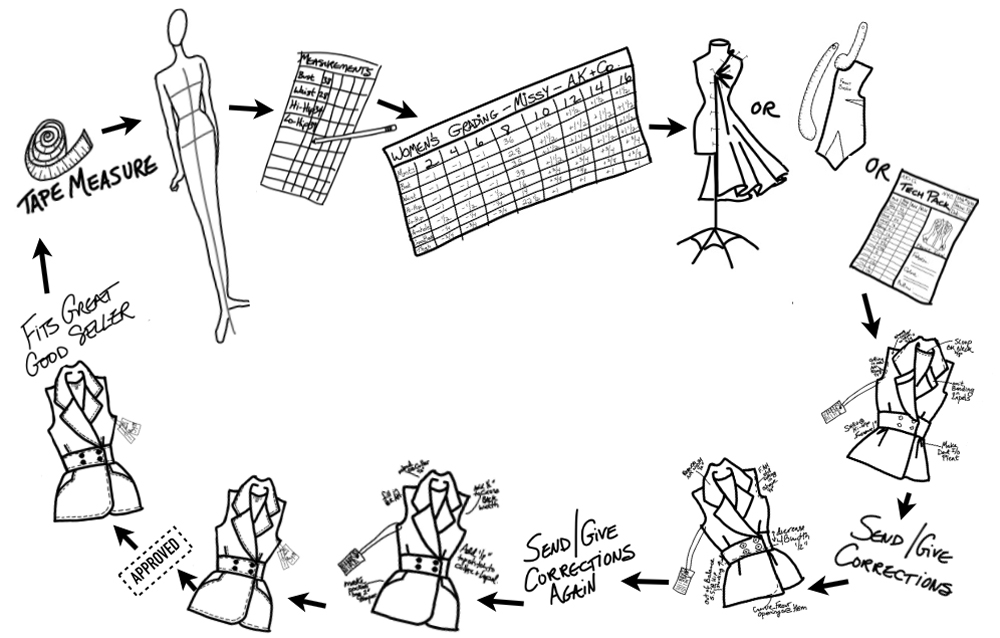

Over the last two decades, the fashion cycle accelerated, and in turn so have fit issues. Trend cycles have become faster and, as a consequence, new styles need to hit the stores at both breakneck speeds and at competitive price points. Many of the steps that used to make our fashion cycle take 12-18 months from concept to delivery therefore needed to be shortened so we could design and ship faster and cheaper. In response to this time crunch, fit samples were unfortunately one of the steps many brands chose to cut out of the production cycle. Less fit samples meant shorter lead times. With speed and low costs being the number one goals for most companies, quality and good fit became comparatively less important.

For many years though, the faster model worked. High street retailers were selling in massive quantities and customers were purchasing big shopping bags full of basement bargains and cared little about how their garments fit. Of course, that fast and furious pace has down trended and things have now changed: Full-price retail sales are down for traditional retailers and fit issues are at an all-time high. In the move to reduce fit samples for shorter leadtimes, great fit was sacrificed. So too, however, was garment longevity.

According to the 2016 BodyLabs Apparel & Footwear Retail Survey Report , in 2015, more than $62 billion worth of clothing and footwear styles were returned due to poor fit and/or incorrect sizing. [1] Additionally, that study reveals that 64% of consumers state the main reason for returning clothing is incorrect fit. In another study out of Iowa State University, [2] 62% of consumers surveyed responded that they could not find clothing that fit well at retail at all.

Reading these consumer studies is upsetting to someone who always thinks about garment fit. I wanted to learn why consumers were experiencing these excessive fit issues, so in October of last year I set out to study how the fashion industry deals with fit today. I knew the current consumer data, but no one seemed to be asking the industry itself. I knew how the industry fit garments twenty years ago – I'd informally surveyed brands back then. But, I wanted to know what changed, so I sent out a survey to fashion professionals who currently work on garment fit.

My questions were: How do those working on fit today feel about fit? How are they fitting? Do they want to change the way they fit? And, if they do agree fit is a problem, why is their work perpetuating the fit problems that we all know exist? [3]

The survey was shared via emails, Facebook and on the Fashiondex website. There were 16 questions and 467 respondents clicked on and were surveyed. The participants ranged across age groups and industry positions. All surveyed were over 18 and working in fashion. The largest age group was 45-55 and 33% of those surveyed were company owners or CEOs, 25% were technical designers, 14% were fashion designers or merchandisers, 9% were production managers, and the remaining 19% held a variety of other fashion company positions.

The results were surprising in that a whopping 94% of those surveyed agreed that garment fit is a problem in retail and manufacturing today. This means we, as an industry, agree that we are putting garments in stores and online that we know do not fit well. When asked, on a scale of one to 10, to what degree does poor-fit contribute to returns, markdowns and chargebacks today, the average response was 7.4. Said differently, today's fashion executives are stating that 74% of their garments are returned due to fit issues. That's higher than the consumer surveys. Are you getting distressed...? I am. Producing these ill-fitting garments is unsustainable. We are in the midst of a climate and population crisis and must find more responsible ways to produce clothing for more people with fewer resources; yet, as an industry, we are producing garments that don't fit well.

There's more! Here are a few other takeaways from the Typeform survey:

- 75% say speed-to-market is the number-one reason why they have increased fit issues; there just is not enough time in the fashion cycle to work on great fit.

- 53% state cost as a factor, stating additional fit samples add expense and today's customer won't pay more.

- The average number of fit samples those surveyed make, fit, and revise per style is: 1.98. This is almost three fewer fit samples per style than twenty years ago, but yet returns due to poor fit/sizing doubled.

- 56% respond that they could obtain better fit for their line if they had more time in production to perfect fit.

- 52% answer they would achieve a better fit if they had more fittings on professional fit models to help them accurately correct fit.

- And, sadly, 21% of companies do not fit garments on human people at all. They check fit on dress forms, via their CAD programs, or by measuring their garment styles flat. If a garment sample never is put on a human, how can we possibly know how the garment will hang on the body and if a person will have full range of motion while wearing it.

- The full survey results will be available through Fashiondex in October, but these are the basic facts. We now know the current fast-fashion supply chain doesn't work for most brands. We agree too many garments get discarded after a few seasons and textile landfill waste has increased. Brands and retailers are suffering and clothing sales are down. So why are we, as an industry, continuing to allow garment fit to suffer? Don't we want our customers to love the fit of our brands?

Is the fast-fashion push worth the sacrifice of the fit of our clothes, the lost dollars from discounts and returns, and the destruction of the environment?

This recent survey of fashion executives confirms we are making less samples and at a faster rate. Economically speaking, perfecting the fit of the clothing we produce is crucial for companies today, especially when our customers – and we ourselves – agree that fit is the main reason so much clothing is returned. We must consider customer satisfaction in order to build our businesses. It is more important now than it ever has been – especially with the increase in platforms for our customers to shop. My takeaway from this study is quite simple: A return to more samples will create better fit, higher quality, and build sustainability and longevity into our products. In short, let's work on perfecting our fit.

Notes

[1] BodyLabs.com; https://www.bodylabs.com/resources/white-papers/2016-apparel-footwear-retail-survey-report/

[2] Shin E., Iowa State University (2014) Exploring consumers' perceptions and satisfaction with apparel in general, http://lib.dr.iastate.edu/cgi/viewcontent.cgi?article=4191&context=etd

[3] I created a Typeform survey. View the survey by typing in this url: https://fitissuesatretail.typeform.com/to/CvI67n